Thermal gel series products are two-component prefabricated thermal grease products, which mainly meet the requirements of low and medium pressure shrinkage molding in use, can realize automatic production, have good contact with electronic products, have low contact thermal resistance and good electrical insulation characteristics. It has the advantages of both thermal pads and thermal grease, compensating for their shortcomings.

The thermal gel inherits the advantages of silica gel. It has good affinity, good weather resistance, high and low temperature resistance, good insulation, and strong plasticity. It can meet the filling of uneven interfaces and the heat transfer requirements of various applications. It has good thermal conductivity, low pressure, low pressure, high compression ratio, high electrical insulation, excellent temperature resistance and new energy, and can be used automatically.

The advantages of continuous operation

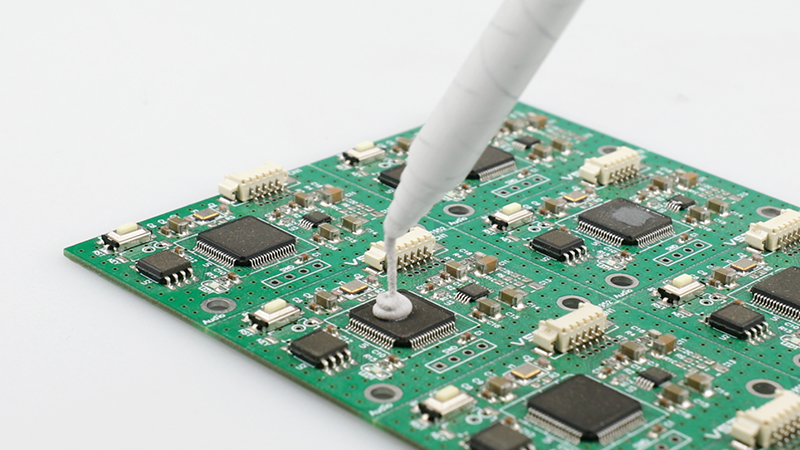

Thermal gel can be directly weighed for use. The common continuous use mode is the dispensing machine, which can achieve fixed point quantitative control, save manpower and improve production efficiency. We should be familiar with this chip cooling method. The similar grease layer between the processor and the heat sink is a principle that transfers the heat released by the processor to the heat sink more quickly and dissipates it.

Similarly, thermal conductive gel can also be used in mobile phone processors. In mobile phone processors, a thermal conductive gel heat dissipating agent similar to silicone grease is used, which is better than just sticking stones to dissipate heat. The film contact effect is better and the heat conduction is faster. Thermal conductive adhesive has a certain adhesive strength, does not release oil, and is not dry, therefore it has a certain level of reliability. Thermal gel is softer than thermal pad, has strong surface affinity, can be compressed to a very low thickness, and significantly improves the heat exchange efficiency.

Compared with thermal pad, thermal gel has more obvious advantages. The thickness of thermal conductive silicone gasket cannot reach the compression degree of thermal gel, which is generally more than 0.5mm, and is easy to break. The thermal resistance is incomparable. It is usually dozens of times higher than the thermal gel, so even if the thermal conductivity is higher than the thermal gel, the thermal conductivity effect is not necessarily dominant. Thermal gel is suitable for automatic production lines, which helps to improve efficiency and reduce costs. However, the automatic construction of thermal conductive pads is difficult to achieve. Therefore, it is recommended to avoid the use of thermal conductive silicone grease and thermal conductive gasket when designing. Thermal gel is more conducive to optimizing design structure and improving product competitiveness.