One of the key technologies for developing new energy vehicles is the battery management system, of which the thermal management system is its core component. The thermal management of new energy vehicle batteries directly affects the power performance, reliability, and safety of the entire vehicle. Currently, thermal countermeasures for new energy vehicle battery packs include air cooling, liquid cooling, phase change cooling, and thermal conduction silicon film, which solve the problems of thermal conduction and heat dissipation of automotive batteries.

Electric batteries are an important factor in promoting the development of new energy vehicles, and power batteries provide power for new energy vehicles; With the advancement of power battery technology, the endurance of new energy vehicles has been greatly improved. However, the higher the power consumption of the battery, the higher the heat emitted during use. Therefore, more effective heat conduction solutions are needed, and thermal conductive silicone rubber gaskets play a significant role in the development of new energy; It is worth mentioning that thermal conductive silicone gaskets have a wide range of applications in power systems and are the preferred interface material for battery thermal conductivity.

The current power batteries are equipped with liquid cooling devices embedded between individual cells, and heat is transmitted to the cooling liquid through an insulation layer that conducts heat. The temperature of the battery pack is controlled by the flow of the cooling liquid, but only a thermal conductive silicone rubber pad is used outside the cooling layer. Thermal conductive silicone gasket is an effective way to dissipate the large amount of heat generated by lithium batteries during operation, while also facilitating conduction between batteries

The use of thermal conductive silicone pads can achieve thermal conductivity and thermal conductivity, while also reflecting thermal conductivity characteristics, resulting in the highest thermal conductivity and thermal conductivity. Of course, when using thermal pads, there is also a cushioning battery pack that can withstand impact and shock absorption, successfully protecting the battery cells. This can effectively protect the battery pack and reduce vibration between modules, achieving the desired thermal conductivity effect.

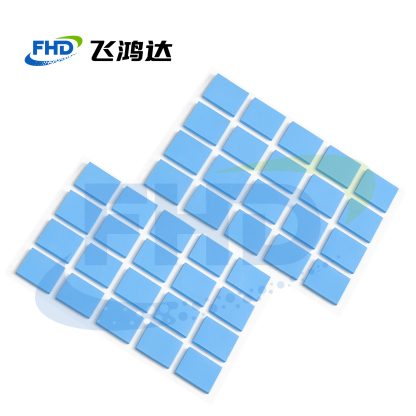

According to the application characteristics and the heat dissipation requirements of power batteries, the thermal conductive silicone pad can play a good role in thermal conductivity in power batteries. Shenzhen Feihongda, as a professional manufacturer of thermal conductive interface materials in China, has a mature product thermal conduction scheme, which can provide high-quality product schemes such as thermal conductive silica gel sheet, thermal conductive silicone grease, thermal conductive silica gel, thermal conductive gel, and thermal conductive mud to meet customer needs in a one-stop manner.