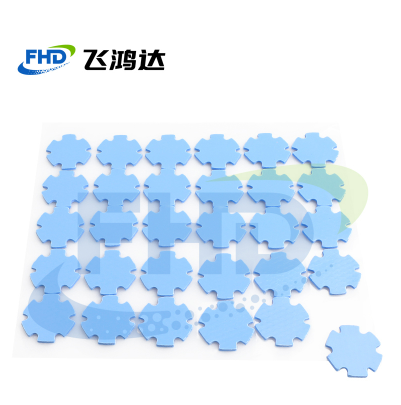

With the continuous development of science and technology, there are a wide variety of materials used in electronic products, and their applications are also very extensive. Among them, thermal conductive silicone sheet is a filling material with strong thermal conductivity and good physical inertness, which will not cause short circuits in the circuit board. Thermal conductivity: Silicone film is a substance synthesized from silicone and some metal oxides. There are many types of thermal conductivity silicone on the market. Generally speaking, thermal conductivity silicone film is used for electronic products and medical equipment that require heat dissipation. There is still a great demand for thermal conductive silicon film now. How do you usually use it? What is the service life of thermal conductive silicone film?

How to use thermal conductive silicone sheet:

Both sides of the thermal conductive silicone film have some natural bonding, so it is also very convenient to use. At the beginning of use, it is necessary to ensure that the two bonding areas are clean, so that the thermal conductive silicone film can be tightly bonded to the thermal conductive silicone film. This method is the same as other things that need to be bonded. Then, the protective film on the thermal conductive adhesive can be torn off, covered on the heat source, and finally compacted. In fact, the steps used for each type of thermal conductive silicone sheet product are the same. This method is fast, simple, and can meet the requirements of easier use. In addition, the thermal conductive silicone sheet can be cut appropriately according to the size of the bonding area needed.

Service life of conductive silicon film:

Generally speaking, if it exceeds 5-10 years, this is a statistical data of big data, and then it is averaged based on the actual situation if the above steps can be followed for standardization. Thermal conductive silicone sheets also have certain buffering, shock-absorbing, and noise reduction functions, as well as other normal auxiliary functions, which can achieve 5-10 years of stability. Due to the differences between the manufacturer and the thermal conductive silicon film itself, the service life of conductive silicon film may be lost, and therefore its service life will also change accordingly. Under the influence of these factors, the service life will vary. In practical applications, natural thermal conductive silicone sheets inevitably have other uncontrollable factors that affect their service life. Therefore, in order to ensure the long-term use of thermal conductive silicon wafers, it is necessary to take reasonable protective measures and operate them according to regulatory requirements, so as to prolong the use time of thermal conductive silicon wafers and save some costs.