Vehicle OBC

The power system of energy electric vehicles is different from traditional fuel vehicles, as the "three electric" system replaces traditional fuel tanks, engines, and transmissions. The "Three Electrics" mainly include the "Big Three Electrics" of the drive system (power battery, motor controller, and motor), as well as the "Small Three Electrics" of the power system (on-board charger OBC, DC/DC converter, and high-voltage distribution box PDU).

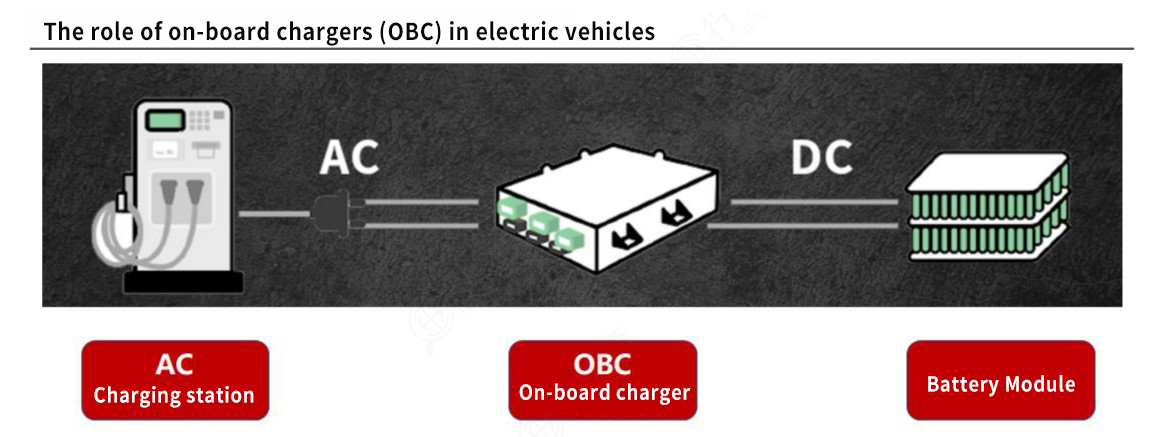

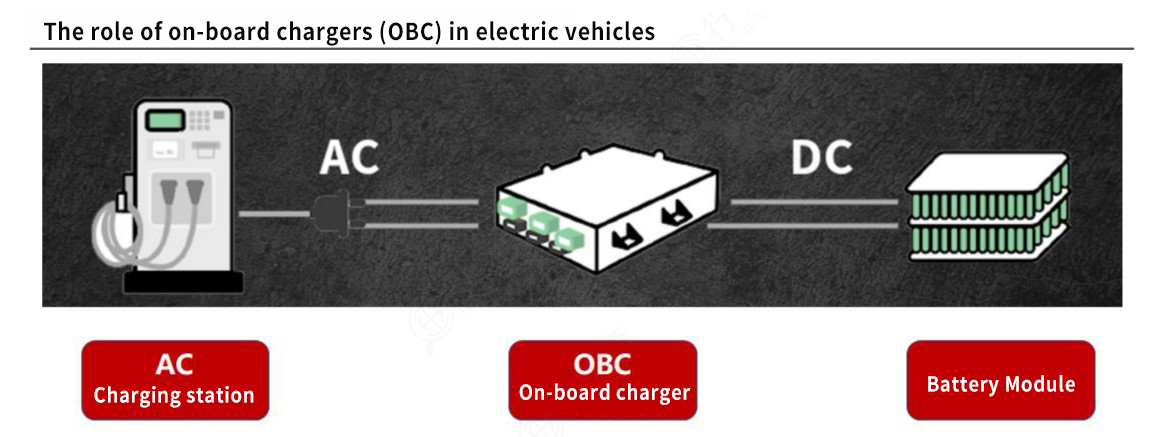

On board charger, abbreviated as OBC, is an important electronic device that connects AC charging stations and converts AC power into DC power. Its working principle mainly includes three aspects: power supply, control logic, and power electronics. Can accept single-phase 220V AC input or three-phase 380V AC input, providing multiple charging power levels such as 3.3kW, 6.6kW, 11kW, or 22kW.

Firstly, the power supply of OBC is usually AC input. Secondly, the OBC has built-in control logic that can convert the input AC power into high-frequency AC power. Through transformer transformation, the high-frequency AC power can be converted into appropriate DC voltage and current to charge the battery.

The on-board charger (OBC) is one of the key components that determine the charging power and efficiency of electric vehicles, and power semiconductors such as diodes, IGBTs, SiC MOSFETs, etc. are the key devices for realizing the conversion between DC and AC power in OBC.

The placement of the on-board charger OBC for each new energy vehicle is not fixed and is arranged according to the manufacturer's design.

Communication Charging Port (Slow Charging) Workflow: Charging Station - Car Charger OBC - Battery Module.

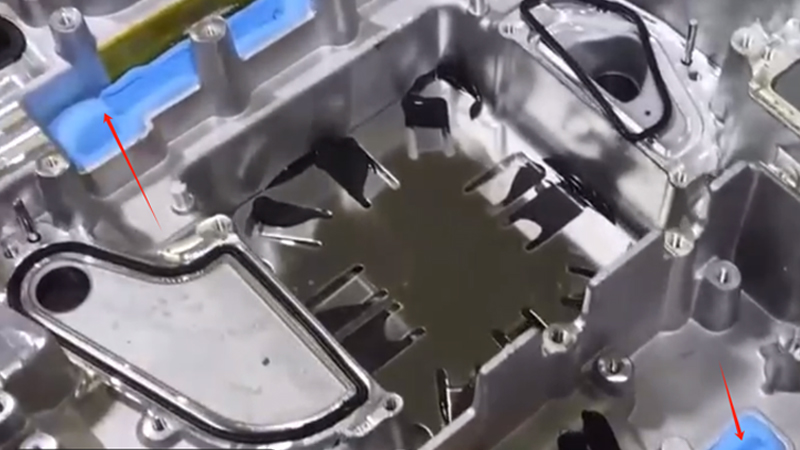

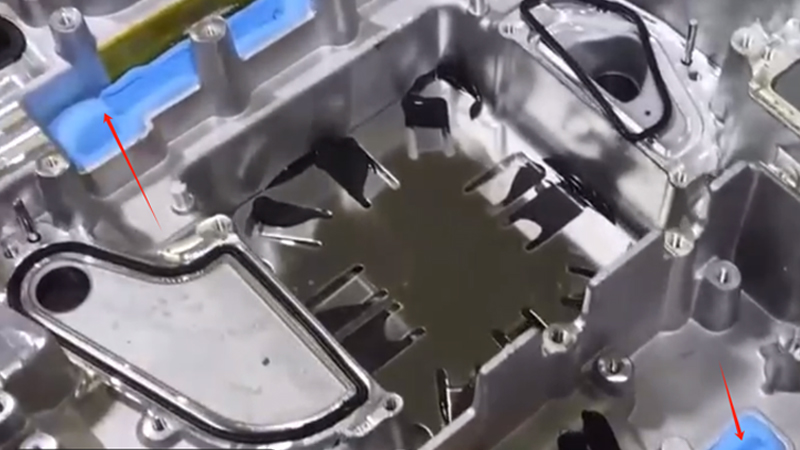

Internal disassembly diagram of OBC for new energy vehicle on-board charger - application of thermal conductive materials

Thermal conductive silicone, RTV adhesive

Characteristics of thermal pad:

The application scenario is different from flat surfaces, and ultra soft thermal pads can be applied to uneven surfaces.

Requirements for UV Three proof Adhesive Characteristics:

1. Temperature 40/humidity 93% 24-168h insulation resistance

2. 85 ℃ 85% RH1000h electrical performance

3. Appearance and adhesion after aging

4. Curing duration

Thermal gel

Thermal pad+thermal insulation sheet with fiberglass composite TIM

Features: Ultra soft+Voltage resistant

-

Previous article:Vehicle Power Battery Pack

-

Next one:Vehicle BMS