Energy storage battery system solution

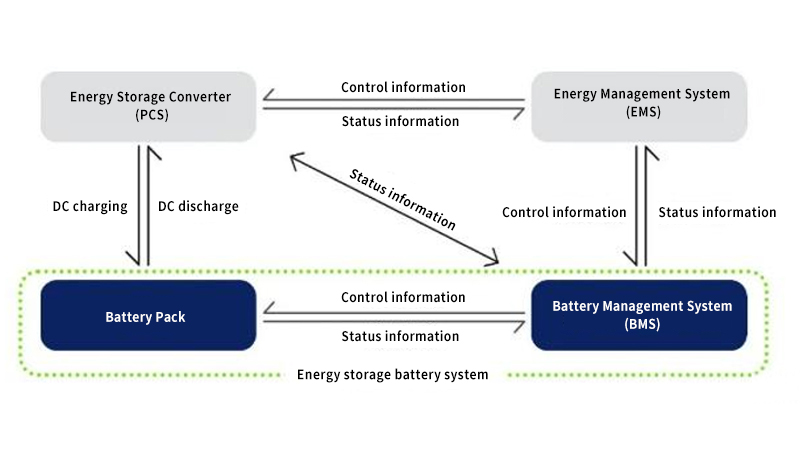

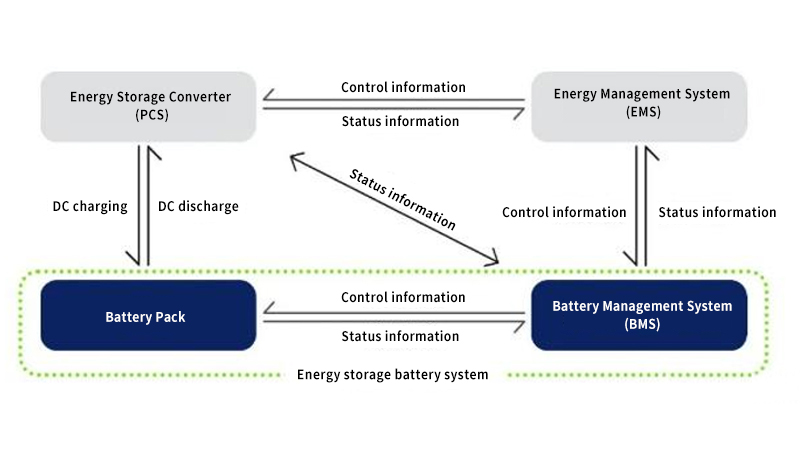

The Battery Energy Storage System (BESS) mainly consists of energy storage batteries, Power Conversion System (PCS), Battery Management System (BMS), Energy Management System, and other components.

Battery Management System (BMS): serves as a perception role, mainly responsible for monitoring, evaluating, protecting, and balancing batteries;

Energy Management System (EMS): Serving as a decision-making role, mainly responsible for data collection, network monitoring, and energy scheduling;

Energy storage inverter PCS: plays an executive role, mainly responsible for controlling the charging and discharging process of the energy storage battery pack, and performing AC/DC conversion.

Application of Thermal Conductive Materials

Thermal conductive silicone

The liquid form of thermal conductive material can be directly applied to the battery cell as an adhesive with the heat sink.

Thermal pad

Thermal conductivity: 2-3 w/m · k

Hardness: 25~35 Shore00

Physical characteristics: ultra soft, high rebound, tear resistant

The adhesive of thermal conductive silicone gasket can be integrated with the automated assembly process, further improving production efficiency and automation level.

Improving the thermal conductivity between the battery pack and the casing effectively transfers the heat accumulated inside the battery pack to the outside, thereby reducing the temperature inside the battery pack, controlling the maximum temperature of the battery, ensuring that the battery is within a suitable temperature range, balancing the temperature between battery cells, and providing strong guarantees for the efficient, safe, and long-life operation of energy storage batteries.

Thermal gel

Thermal conductivity: 1~3.5 w/m · k

Hardness: 40~75 Shore00

Physical properties: ultra-high compliance, suitable for low stress interfaces

The application has excellent wettability

Usage: Used for heat dissipation of batteries and base side panels, mainly for heat dissipation of power components.

Function: It can be used for heat dissipation at the top and side walls of the shell, fixing seismic resistance, increasing the thermal conductivity area of non parallel components, and reducing interface thermal resistance. As a thermal interface material, it helps to dissipate heat from battery cells, has good vibration resistance, fills tooling tolerances, and has a high degree of automation.

-

Previous article:Inverter

-

Next one:Photovoltaic Panels