Plant Lights Solution

When plant lights (such as LED plant growth lights) are in operation, the light source module (especially high-power LED chips) will generate a large amount of heat. Poor heat dissipation can lead to decreased light efficiency, shortened lifespan (LED lifespan may decrease by 50% for every 10 ℃ increase in temperature), and even pose safety hazards. The choice of interface material, as a key bridge for heat transfer from heating components such as LED chips and driving power supplies to heat dissipation structures (such as heat dissipation fins and metal shells), directly affects the heat dissipation efficiency. The following are commonly used heat dissipation interface materials and their characteristics for plant lamps:

1、 Thermal grease (heat dissipation paste)

Ingredients: Based on silicone oil as the carrier, mixed with thermal conductive fillers (such as alumina, boron nitride, silicon carbide, etc.), in a paste form.

Characteristic:

The thermal conductivity range is wide (0.8-10W/m · K), which can adapt to the needs of different power plant lamps;

Good fluidity, can fill the micro gaps between the LED bead base and the heat dissipation substrate (such as aluminum substrate), greatly reducing the contact thermal resistance;

Non curing, strong chemical stability, not easily dried up after long-term use, suitable for scenarios where plant lamps work continuously for a long time;

Attention should be paid to uniform application (thickness is usually controlled at 0.1-0.3mm, excessive thickness may increase thermal resistance).

Application scenarios: The contact surface between the light beads of small and medium power LED plant lights and the aluminum substrate, as well as between the driving power chip and the heat sink.

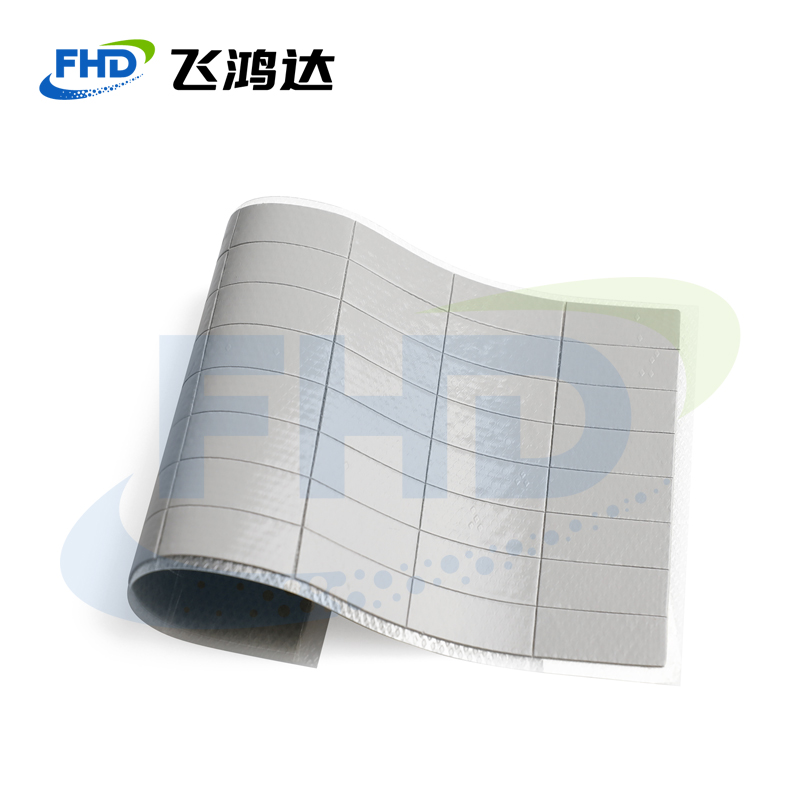

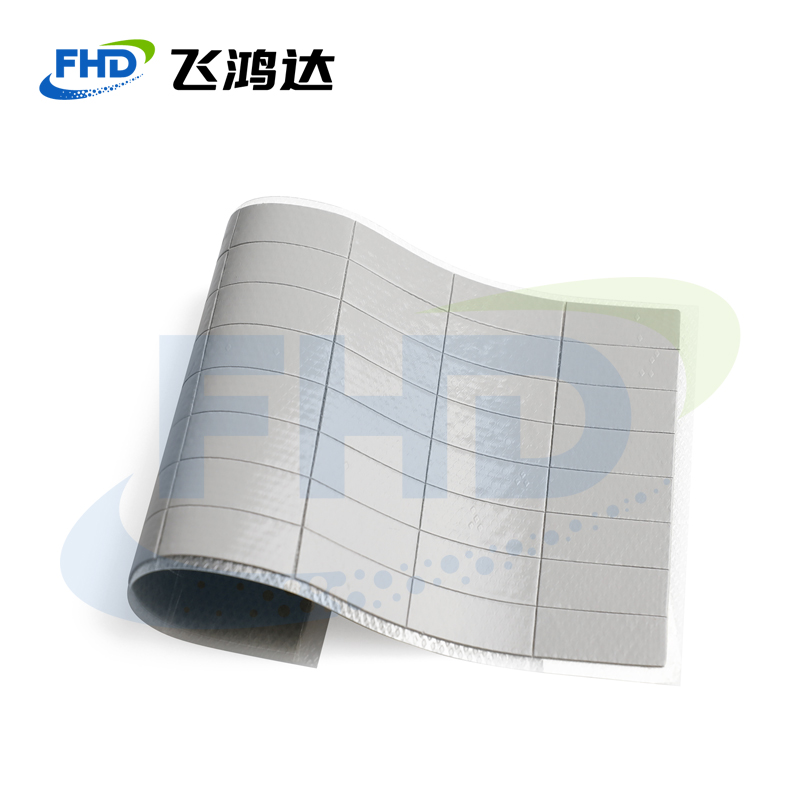

2、 Thermal pad

Ingredients: Made of silicone as the substrate, filled with thermal conductive powder (such as alumina, zinc oxide), can be prefabricated into sheets, some with adhesive backing.

Characteristic:

Has a certain degree of elasticity and flexibility, can fit irregular surfaces (such as the gap between the drive power housing and the heat dissipation fins), and is suitable for uneven contact surfaces caused by assembly tolerances in plant lamps;

Excellent insulation properties (volume resistivity usually>10 ¹⁴Ω· cm), suitable for insulation and heat dissipation between LED circuits and metal heat dissipation structures, avoiding the risk of short circuits;

The thickness range is wide (0.2mm-5mm), and can be flexibly selected according to the gap between components. It is easy to install (no need to apply, direct bonding).

Application scenarios: Thermal filling between the driving power module and heat dissipation fins of high-power plant lamps, as well as between aluminum substrates and metal shells.

3、 Thermal gel

Ingredients: semi-solid gel, silicone as the base material, mixed with high proportion of thermal conductive filler, thicker than silicone grease, softer than silicone pad.

Characteristic:

High thermal conductivity (1.5-8W/m · K), combining the low thermal resistance of silicone grease with the ease of operation of silicone pads, no need for manual application, can be directly attached;

The compression capacity can reach 30% -50%, which can adapt to the gap changes caused by thermal expansion and contraction of components in plant lamps (such as small deformations of aluminum substrates after long-term operation);

No silicone oil precipitation, avoiding contamination of LED beads or circuit components (especially suitable for plant lamps with high cleanliness requirements).

Application scenario: The bottom heat dissipation of high-power COB (integrated chip) light sources between multiple LED bead arrays of integrated plant lights and large area heat dissipation plates.

4、 Thermal conductive phase change material

Ingredients: Based on paraffin or polymer, mixed with thermal conductive filler, solid at room temperature, and turns into liquid after reaching the phase transition temperature (usually 50-70 ℃).

Characteristic:

Absorbing a large amount of latent heat during phase change, delaying the temperature rise of LED chips, suitable for the intermittent working mode of high-power operation during the day and low-power operation at night of plant lights;

When in liquid state, it can fully infiltrate the contact surface, fill gaps, and automatically adapt to the gap changes caused by thermal expansion and contraction when the thermal resistance is lower than in solid state;

Good insulation, partially self-adhesive, easy to install, and no risk of flow after curing.

Application scenarios: Cooling between COB light source and heat dissipation fins of high-power plant lamps, and cooling of high-power capacitors in driving power supplies.

-

Previous article:Stage Spotlights

-

Next one:Absentee Light