Cooling solution for servo controller

As a precision electrical equipment, servo controllers generate a large amount of heat from their internal power devices (such as IGBT, MOSFET, rectifier bridge, etc.) during high-frequency switching operation. The heat needs to be efficiently transferred to the heat dissipation structure (such as heat sink, water-cooled plate) through interface materials, while also meeting requirements such as insulation, temperature resistance, and compatibility with installation tolerances. The following are recommendations for highly adaptable interface materials for servo controller scenarios:

1. High thermal conductivity silicone grease (thermal conductivity coefficient 3-8W/m·K)

Advantages: Good fluidity, can fill micron sized gaps, extremely low thermal resistance (0.005-0.02 ℃·in ²/W); No curing properties, no cracking after long-term use, suitable for small deformations caused by thermal expansion and contraction of power devices; Moderate cost, suitable for batch application (with automated dispensing).

Attention: The coating thickness should be controlled (0.05-0.2mm) to avoid excessive overflow and contamination of the circuit.

2. Thermal conductive gel (thermal conductivity 4-10W/m·K)

Advantages: Semi solid form, no need for manual application, can be pre formed or glued for construction, suitable for automated production; Compression ratio of 30% -50%, compatible with device installation tolerance (± 0.1mm); No silicone oil precipitation, avoiding corrosion of PCB or metal contacts, with higher reliability than ordinary silicone grease.

Applicable scenarios: Between IGBT modules and water-cooled plates of medium to high power servo controllers (over 5kW).

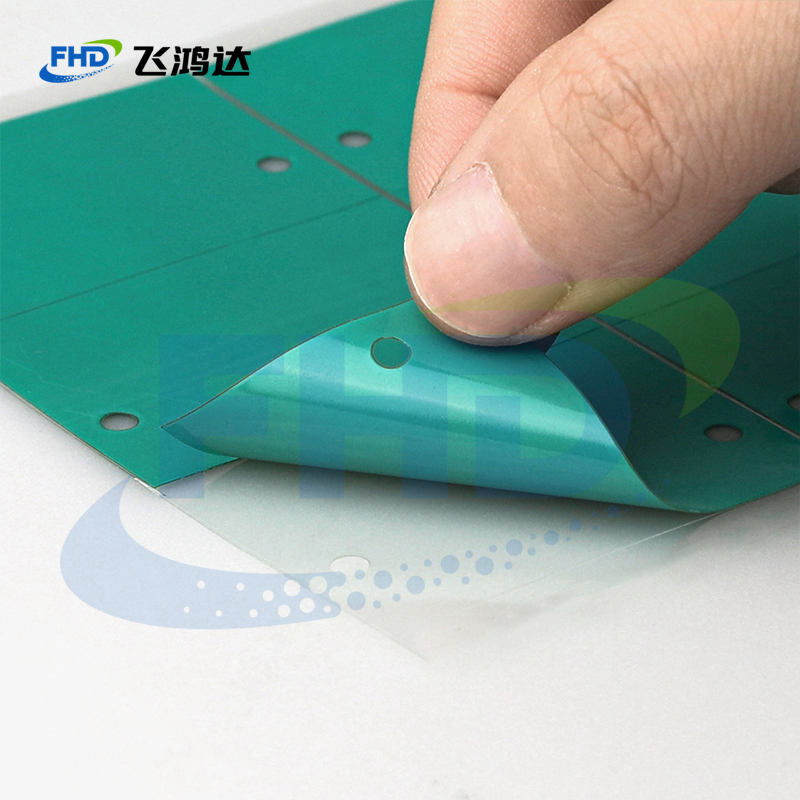

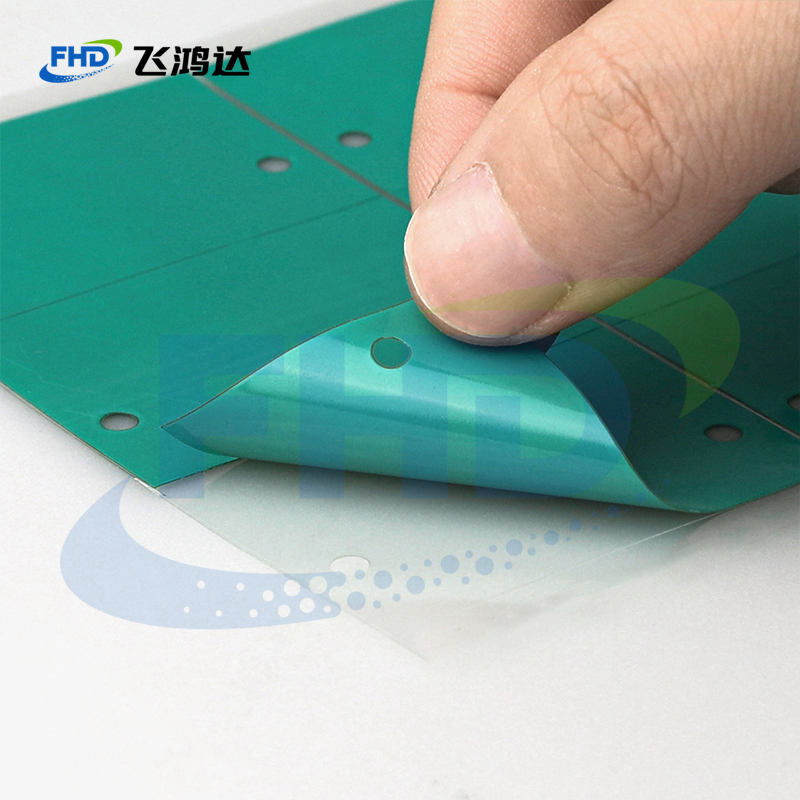

3. Thermal conductive silicone pad (thermal conductivity 1.5-5W/m·K, with backing adhesive)

Advantages: Soft and elastic (hardness 30-60 Shore OO), can be attached to the surface of irregular components such as capacitors and resistors; Excellent insulation performance (volume resistivity>10 ¹⁴ Ω· cm), avoiding the risk of short circuit; The adhesive design is easy to install and fix, suitable for modular heat dissipation in compact spaces of servo controllers.

Thickness selection: Based on the gap between the component and the heat sink, prioritize 0.3-1mm (excessive thickness will increase thermal resistance).

4. Thermal conductive phase change material (phase change temperature 50-70 ℃, insulation type)

Advantages: Solid state at room temperature, easy to transport and install; After reaching the working temperature, it liquefies and automatically fills the interface gaps (reducing the thermal resistance to below 0.015 ℃· in ²/W); The phase transition process can absorb some heat, delay the peak temperature of components, and is suitable for temperature fluctuation scenarios during servo controller start stop.

Applicable scenarios: Heat dissipation between the driver board and the metal casing (such as the built-in heat sink of small servo drives).

5. Thermal conductive sealant (organic silicon system, thermal conductivity 1.0-2.5W/m·K)

Advantages: After liquid infusion, it solidifies into an elastic body, which can completely wrap the small heating elements (such as drive chips and inductors) inside the servo controller, while filling the gaps to achieve overall heat dissipation; It has waterproof, shockproof, and insulation functions, suitable for servo controllers in outdoor or harsh industrial environments (such as machine tools and robots).

-

Previous article:UPS Power Supply

-