Server Solution

The servers and switches in data centers currently use methods such as air cooling and liquid cooling for heat dissipation. In actual testing, the main heating component of the server is the central processing unit (CPU), which generates about 80% of the total heat generated by the server.

In addition to air cooling or liquid cooling, suitable thermal interface materials (TIM) can also assist in heat dissipation and reduce the thermal resistance of the entire thermal management process. For thermal interface materials, the importance of high thermal conductivity is self-evident, but in practical applications, the main purpose of many thermal solutions is to reduce thermal resistance to achieve rapid heat transfer from the processor to the heat sink.

In thermal interface materials, thermal grease and phase change materials have better gap filling ability (interface wetting ability) compared to thermal pads or liquid gap filling materials, achieving a very thin adhesive layer and providing lower thermal resistance. However, thermal conductive silicone grease is often prone to migration or extrusion over time, resulting in loss of filler and loss of heat dissipation stability.

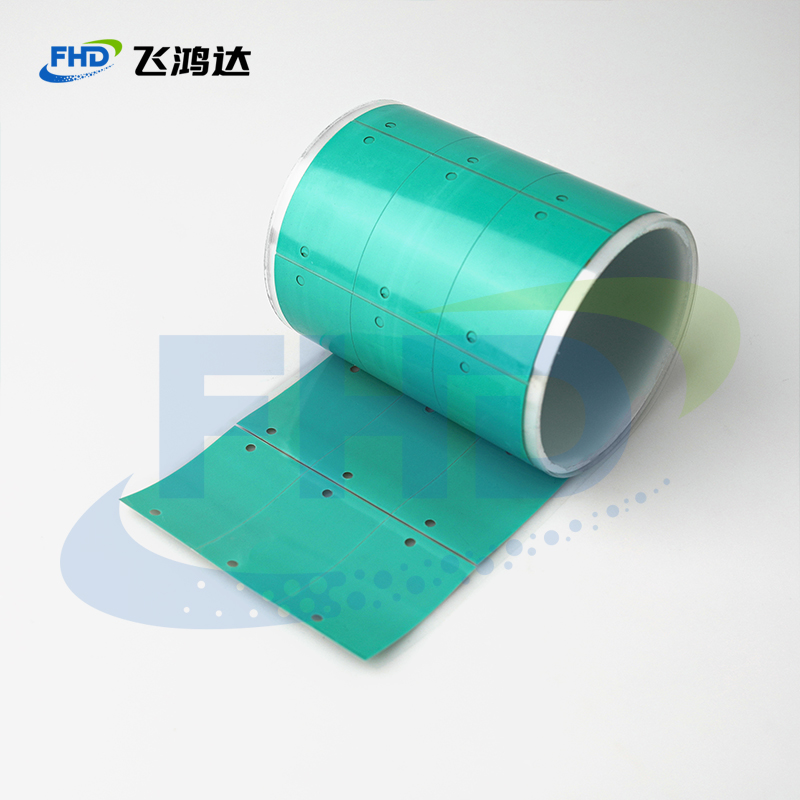

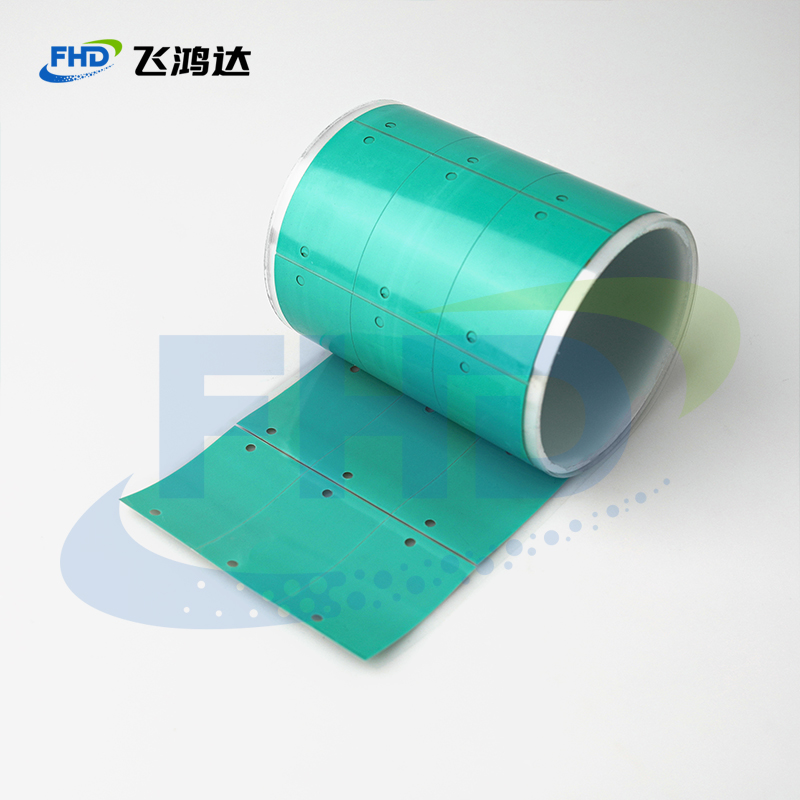

High performance phase change materials are a great choice as they remain solid at room temperature and only soften when the specified temperature is reached, providing stable protection for electronic devices. In addition, some phase change material formulations can also achieve electrical insulation function.

-

-

Next one:Communication Base Station